Factory wholesale Small Shell And Tube Heat Exchanger - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta

Factory wholesale Small Shell And Tube Heat Exchanger - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta Detail:

National invention patent

The characteristics and treatment method of furfural wastewater: It has strong acidity. The bottom wastewater contains 1.2%~2.5% acetic acid, which is turbid, khaki, light transmittance <60%. In addition to water and acetic acid, it also contains extremely A small amount of furfural, other trace organic acids, ketones, etc. The COD in the wastewater is about 15000~20000mg/L, BOD is about 5000mg/L, SS is about 250mg/L, and the temperature is about 100℃. If the waste water is not treated and discharged directly, the water quality will inevitably be seriously polluted and the structure of the ecological environment will be destroyed. The general treatment methods mainly include: chemical method, biological method (upstream aerobic reaction, filtered aerobic reaction, etc.), aerobic treatment process (SBR reaction, contact oxidation reaction), among which aerobic treatment is another after anaerobic treatment A treatment process, in order to ensure the standard of effluent water quality, is an indispensable treatment process in the treatment of furfural wastewater. However, in the project commissioning stage, aerobic commissioning will waste a lot of time and money, which will increase the cost of water treatment projects, such as commissioning. If it is not good, it will make the overall process unable to run, so aerobic debugging is very important to the overall project, but nutrients are essential in aerobic debugging.

Waste water produced by furfural is belong to Complex organic wastewater, which contain cetic acid, furfural and alcohols, aldehydes, ketones, esters, organic acids and many kinds of organics, PH is 2-3, high concentration in COD,and bad in biodegradability.

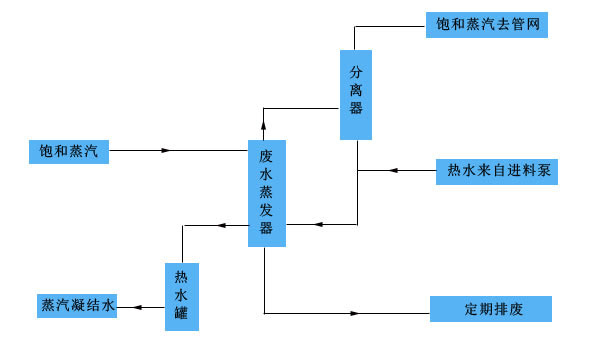

The process regard saturated steam as heat source, evaporation system make.

Waste water vaporized, boost pressure to reach production requirement, recycle the furfural and heat from the waste water to realize waste water recycle in production process. The device adopt automatic program to control.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Factory wholesale Small Shell And Tube Heat Exchanger - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta , The product will supply to all over the world, such as: Danish, Qatar, Algeria, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!