Cheapest Price Edible Alcohol Plant - Evaporation and crystallization technology – Jinta

Cheapest Price Edible Alcohol Plant - Evaporation and crystallization technology – Jinta Detail:

Molasses alcohol waste liquid five-effect evaporation device

Overview

Source, characteristics and harm of molasses alcohol wastewater

Molasses alcohol wastewater is high-concentration and high-color organic wastewater discharged from the alcohol workshop of the sugar factory to produce alcohol after the fermentation of molasses. It is rich in protein and other organic matter, and also contains more inorganic salts such as Ca and Mg and higher concentrations. SO2 and so on. Normally, the pH of alcohol wastewater is 4.0-4.8, COD is 100,000-130,000 mg/1, BOD is 57-67,000 mgSs, 10.8-82.4 mg/1. In addition, most of this kind of wastewater is acidic, and the color is very high, brown-black, mainly including caramel color, phenolic color, Maillard color and so on. Since the waste liquid contains about 10% solids, the concentration is low and cannot be used. If it is directly discharged into rivers and farmland without treatment, it will seriously pollute the water quality and the environment, or cause soil acidification and compaction, and the growth of crop diseases. How to deal with and use the molasses alcohol waste liquid is a serious environmental problem facing the sugar industry.

Molasses alcohol waste liquid is highly corrosive and has high chroma, which is difficult to remove by biochemical method. Concentrated incineration or high-efficiency liquid fertilizer is the most thorough treatment plan at present.

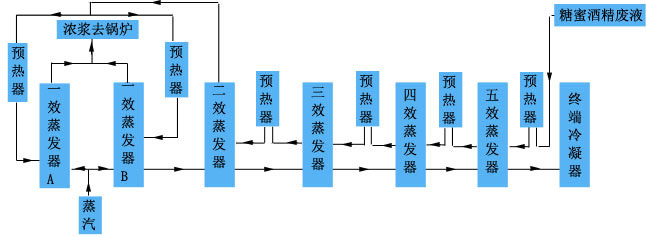

The device adopts a five-effect forced circulation step-down evaporation system, with saturated steam as the heat source, one-effect heating and five-effect work. The molasses alcohol waste liquid with a concentration of 5 to 6% is concentrated and evaporated, and a concentrated slurry having a concentration of ≥ 60% is sent to the boiler for incineration, and the generated heat substantially satisfies the steam for the device. Evaporate the condensed water back to the previous section for dilution water.

Second, the process flow chart

Third, the process characteristics

1. Set the spare evaporator to clear the material, which can realize non-stop cleaning and ensure continuous production.

2. The device adopts automatic program control to save labor costs.

3. High processing efficiency and stable operation.

4. By using thick slurry to return to the boiler, molasses can produce alcohol without adding fuel.

5. A spare evaporator is set for the discharge effect, which can realize non-stop cleaning and ensure continuous production.

6. Alcohol can be produced from molasses without adding fuel through thick slurry to the boiler for reuse and molasses.

Product detail pictures:

Related Product Guide:

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for Cheapest Price Edible Alcohol Plant - Evaporation and crystallization technology – Jinta , The product will supply to all over the world, such as: belarus, Greece, Haiti, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.